様々な分野のお客様に、Quality Cost Delivery Service に優れた、商品とサービスをご提供しています。

- ※

- それぞれの画像上に、マウスを重ねると仕様を確認することができます。

- また、画像をクリックして画像を拡大することができます。

精密部品

material:PC GF20%

accuracy:

-flatness=0.02

-position=±0.0075

-roughness=general 0.8μm, partial 0.4μm

(gear)

-module=0.2

-JGMA=class3

-base tangent length=+0/-0.02

treatment:Spray(thickness 5~8μm)

cavities:4

material:PC GF20%

accuracy:

-flatness=0.02

-position=±0.02

-roughness=general 0.8um, partial 0.4um

(cam)

-groove=+0.01/-0

-position=±0.015

cavities:4

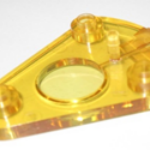

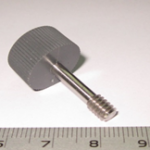

material:POM

accuracy:

-cam R=±0.02

-hole=φ2H8(+0.014/0)

(gear)

-module=0.3

-JGMA=class3

-base tangent length=+0/-0.03

cavities:4

material:PC GF20%

accuracy:

(shaft)

-diameter=+0.015/-0

-position=±0.03

-concentricity=±0.03

-perpendicity=±0.03

cavities:4

material:LCP GF30%

accuracy:

-roughness=0.8um

-burr=marked:no burr,others:0.03or less

(Hole)

-position=±0.03

-diameter=+0.025/-0

cavities:4

material:PC GF30%

accuracy:

(Hole)

-position=±0.02

-diameter=+0.015/-0

cavities:4

material:PC GF30%

accuracy:

(Hole)

-position=±0.03

-diameter=+0.025/-0

cavities:4

material:PC GF30%

accuracy:

(Hole)

-position=±0.025

-diameter=+0.015/-0

cavities:4

material:PC GF30%

accuracy:

(Hole)

-cam=±0.035

cavities:4

material:POM

accuracy:

-position=±0.05

-shaft=+0/-0.03

-parallelism=0.1

number of data:853

ギア(歯車)

material:PC GF30%

accuracy:

-module=0.3

-diameter=+0.006/-0.031

-spec:number of thread=1 start thread, Lead angle=8°58’21”

cavities:4

material:POM

accuracy:

(Worm Gear)

-module=0.4

-diameter=+0/-0.05

-spec:number of thread = 1 start thread, Lead angle = 4°30′

(Helical Gear)

-module=0.4

-diameter=-0/-0.05

-spec:number of teeth=10,Lead angle = 2°50′

cavities:4

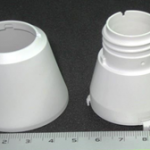

耐熱品

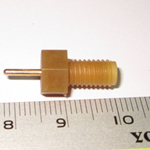

material:PPS(GF40%)(High Performance Engineering Plastics)

accuracy:

-Thread=M6

-P=0.75(pitch diameter=5.513)

Thread Ring Gauge=Control

-Go:5.513(+0.02/-0)

-NG:5.491(+0.006/-0.018)

cavities:4

material:PPS(GF40%)

accuracy:

(hole)

-diameter=±0.05

(groove)

-pitch=+0.02/-0

cavities:4

Feature:Since wall thickness is large,require the adjustment of the deformation by shrinkage.

cavities:4

material:REI

accuracy:

(hole)

-diameter=+0.015/-0

cavities:4

Feature:Since especially the cost of materials is expensive, runner size and defective product influence cost greatly.

Therefore, advanced mould design and manufacturing management are needed.

material:REI

accuracy:

(hole)

-diameter=+0.03/-0

取数:2

material:PPS(GF20%)

cavities:4

material:LCP(GF30%)

accuracy:

-flatness=0.2

-hole=±0.06

cavities:4

化粧外観品

ABS

- Injection Molding

- Spray

- Screen Print

ABS

- Injection Molding

- Spray

- Pad Print

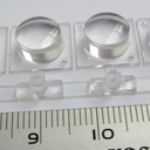

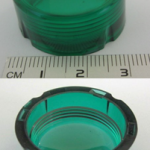

PC

accuracy:lens

PC

accuracy:Mirror Surface

ABS

accuracy:Texturing(Satin)

ABS

- Injection Molding

- Spray

PC

POM

- Injection Molding

- Screen Print

- Glueing

Part1=ABS

- Injection Molding

- Ultrasonic Welding

- Spray

- Screen Print

Part2=TPE

- Injection Molding

Part3=ABS

- Injection Molding

- Ultrasonic Welding

- Spray

Part4=ABS

- Injection Molding

- Spray

material:PC+PBT

accuracy:

-hole position=±0.05

-flatness=0.05

processing:

- Injection Molding

- screw insert=brass

- Vapor cleaning

- pad print

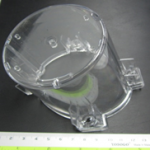

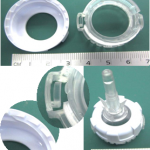

material:PC

accuracy(outer&inner):

-coaxiality=0.15

-thread=M25x1.5-6H

-surface=Mirror Surface

PET GF15%

- Injection Molding

- screw insert=brass

- Vapor cleaning

- pad print

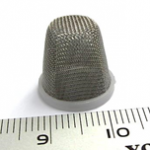

メタル インサート部品

material:

-metal=Stainless net

- Stamping process

– – Blanking

– – Drawing

– – Trimming - Washing process

– – Vapor cleaning

-resin=POM

- Injection process

– – Insert molding

material:

-metal=Stainless Steel

- Washing process

– – Vapor cleaning

-resin=PBT

- Injection process

– – Insert molding

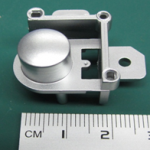

material:

-metal=Brass

- Washing process

– – Vapor cleaning

-resin=PBT

- Injection process

– – Insert molding

material:

-resin=PPSU(Polyphenylsulfone)

- Injection process

– – Insert molding

material:

-metal=Brass

- Washing process

– – Vapor cleaning

-resin=PPS GF40%

- Injection process

– – Insert molding

アセンブリ部品

Part1=PC GF20%

- Injection Molding

Part2=PC GF20%

- Injection Molding

- Ultrasonic Welding

Part3=Brase Nut

- Washing Process

– – Vapor Cleaning - Ultrasonic Welding

Part1=POM

- Injection Molding

- Pad Print

Part2=POM

- Injection Molding

- Heat Welding

Part3=POM

- Injection Molding

- Pad Print

Part4=POM

- Injection Molding

- Pad Print

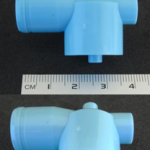

Part1~7=PPO

- Injection Molding

Part8=SUS spring

- Washing Process

– – Vapor Cleaning

Part9=SUS

- Washing Process

– – Vapor Cleaning

Assy=ultrasonic welding

testing=air Leak test

material:

-Part1=PC

-Part2=PBT

processing:

- Injection Molding(Part 1)

- Injection Molding(Part 2 Insert Molding)

- Protection Film for Lens

- Gasket

- Screw Insert

- Labeling

material:

-Part1=PA6 ( injection molding )

-Part2=Metal

-Part3=Washer

-Part4=Spring

-Assy=Caulking of metal by press machine

医療(メディカル)

material:PC

Accuracy:

-hole=±0.01

-surface=Mirror surface

material:PC

Accuracy:

-hole=±0.01

-surface=Mirror surface

material:PC / ABS

material:HDPE(High Density Polythylene)

Accuracy:

-hole=±0.05

material:PP

material:PA66